SES and Yulista win contract supporting the Prototype Integration Facility

Defense Systems and Solutions (DSS), a joint venture between Science and Engineering Services, LLC (SES) and Yulista Integrated Solutions, LLC (YIS) was recently awarded a $4.73B contract supporting the Aviation and Missile Research Development and Engineering Center (AMRDEC) Prototype Integration Facility (PIF) located at Redstone Arsenal, AL. DSS, a SBA approved 8(a) joint venture, is a strategic partnership between SES and YIS.

The SES/YIS Team continues to support AMRDEC’s PIF mission by providing single-source convenience, tactical and technical solutions for warfighters quickly through rapid response prototyping, engineering, manufacturing, and technical support for the Department of Defense and other government agencies. These efforts support new and existing platforms, systems, subsystems, parts, items, and components, and emerging future technology.

SES is proud to continue its support to the AMRDEC and PIF which first began in 2002 as part of the original PIF contract award providing rapid response hardware solutions to the Warfighter in theater. SES support to the AMRDEC PIF contract has continued unabated for each of the past 16 years. This contract award to DSS is indicative of high quality products produced by a highly skilled, dedicated and professional workforce, committed to supporting our men and women in uniform. For more information about SES visit sesllc-us.com.

SES upgraded AH-1F featured at Special Operations Forces Exhibition

SES is a recognized leader in system modification, integration, and training of rotary wing platforms. In May, SES delivered the first of several Jordanian Royal Air Force upgraded AH-1F aircraft. One of the initial aircraft was demonstrated at SOFEX 2018 in Amman, Jordan. This first delivery represents the first of several deliveries and systems upgrades that will provide the Jordanian Royal Air Force with increased AH-1 warfighting capabilities.

SES is a recognized leader in system modification, integration, and training of rotary wing platforms. In May, SES delivered the first of several Jordanian Royal Air Force upgraded AH-1F aircraft. One of the initial aircraft was demonstrated at SOFEX 2018 in Amman, Jordan. This first delivery represents the first of several deliveries and systems upgrades that will provide the Jordanian Royal Air Force with increased AH-1 warfighting capabilities.

SES delivers the second of multiple Spanish SH-60 upgraded aircraft

This April, SES delivered the second of mutiple SH-60F aircraft to the Spanish Navy. As part of Foreign Militray Sale transaction, SES was selected to design, modfiy, and install multiple upgrades to aircraft previously deemed excess US Navy aircraft. As part of this process, SES returned the aircraft to flight status then designed and installed specific upgrades requested by the Spanish Navy. SES is an industry leader in the design and installation of upgraded systems while supporting the US Army, Navy, Air Force, and Coast Guard, and providing critical support to our foreign partners.

This April, SES delivered the second of mutiple SH-60F aircraft to the Spanish Navy. As part of Foreign Militray Sale transaction, SES was selected to design, modfiy, and install multiple upgrades to aircraft previously deemed excess US Navy aircraft. As part of this process, SES returned the aircraft to flight status then designed and installed specific upgrades requested by the Spanish Navy. SES is an industry leader in the design and installation of upgraded systems while supporting the US Army, Navy, Air Force, and Coast Guard, and providing critical support to our foreign partners.

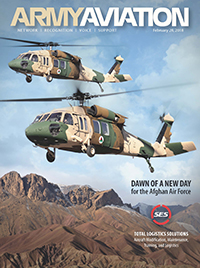

SES Accomplishments in Afghanistan Air Force fielding highlighted in AAAA Magazine

On January 7, 2018 SES modified and delivered UH-60A aircraft were featured on the cover of the Army Aviation Association of America’s Magazine. As part of the Afghanistan Air Forces modernization plan, SES was selected to modify, integrate systems, deploy, sustain and train Afghan pilots on the UH-60A. SES continues to deliver aircraft on a monthly basis and maintain aircraft at well beyond US Army readiness goals. In May of this year, the first Afghanistan Blackhawks executed combat missions with an all Afghan crew, less than 7 months after initial fielding and training start dates. SES is proud to support this vital program that brings increased capability and capacity to the Afghanistan Air Force.

On January 7, 2018 SES modified and delivered UH-60A aircraft were featured on the cover of the Army Aviation Association of America’s Magazine. As part of the Afghanistan Air Forces modernization plan, SES was selected to modify, integrate systems, deploy, sustain and train Afghan pilots on the UH-60A. SES continues to deliver aircraft on a monthly basis and maintain aircraft at well beyond US Army readiness goals. In May of this year, the first Afghanistan Blackhawks executed combat missions with an all Afghan crew, less than 7 months after initial fielding and training start dates. SES is proud to support this vital program that brings increased capability and capacity to the Afghanistan Air Force.

SES continues to executive UH/HH-60M New Equipment Training for the Army

SES has provided Pilot, Instructor Pilot, Maintenance Test Pilot, non-rated Crewmember and Maintainer qualification at home station in support of the UHPMO UH/HH-60M Fielding for many years to more than 14 Brigade level formations in the active and reserve component. In addition, SES provides a robust maintenance team consisting of aircraft and avionic mechanics, quality inspectors, sheet metal repairers, and aviation life support equipment technicians who maintain these aircraft throughout the training process until the unit’s maintenance personnel are trained to take over the mission. Bringing this necessary training to the unit’s location supports the Soldier, their family, and Army requirements.

SES has provided Pilot, Instructor Pilot, Maintenance Test Pilot, non-rated Crewmember and Maintainer qualification at home station in support of the UHPMO UH/HH-60M Fielding for many years to more than 14 Brigade level formations in the active and reserve component. In addition, SES provides a robust maintenance team consisting of aircraft and avionic mechanics, quality inspectors, sheet metal repairers, and aviation life support equipment technicians who maintain these aircraft throughout the training process until the unit’s maintenance personnel are trained to take over the mission. Bringing this necessary training to the unit’s location supports the Soldier, their family, and Army requirements.

In addition, SES has conducted additional NET for foreign customers at our Huntsville facilities. This additional capability allows SES to also train HQDA directed students and host trainees from other services and serves as an example of how the flexibility of the NET can shift to meet the evolving needs of the US Government.

The SES NETT provides the following:

NETT Capabilities:

- ATARRS recognized, ASI producing training.

- Academic, simulation, hands-on and flight training resulting in qualification.

- Full spectrum maintenance support to include scheduled and unscheduled maintenance.

- Aircraft acceptance/induction, MWO installation and upgrades.

NETT Benefits:

- Completely mobile; training conducted at unit’s home station.

- Entirely self-contained (maintenance, training, operations); no burden on unit.

- Fully compliant with Army/DoD requirements. No OEM involvement.

- Cost effective.

NETT Schedule:

- 159th CAB, Fort Campbell - Completed

- 1st CAB, Fort Riley - Completed

- Wisconsin NG - Completed

- 82nd CAB, Fort Bragg - Completed

- 101st CAB, Fort Campbell - Completed

- Swedish Transition - Completed

- 10th CAB, Fort Drum - Completed

- 7-101st Fort Campbell - Completed

- 16th CAB, JBLM - Completed

- 25th CAB - Completed

- 3rd CAB, HAAF - Completed

- NGB, WAATS, Marana, AZ – Completed

- Ft. Riley - Completed

- Ft. Bliss - Completed

- Ft Hood - On-going

Successful Delivery of First HH-60G through L2G

On 28 June 2016, Science and Engineering Services (SES), LLC delivered the first HH-60G PAVE HAWK helicopter to the U.S. Air Force in a ceremony conducted at the SES West Aviation Integration Facility. The HH-60G PAVE HAWK helicopter has a primary mission to conduct Combat Search and Rescue (CSAR) to recover downed aircrew members and other isolated personnel in austere and hostile territory.HH-60G PAVE HAWKS have been lost to combat, training, and civil rescue missions. To maintain CSAR capability, the short-term solution for the HH-60G is the Operational Loss Replacement (OLR) Program. The OLR program replaces lost aircraft and addresses the immediate need to maintain the operational availability of legacy HH-60Gs. The current approach is to receive UH-60Ls from the Army, then modify the UH-60Ls to the current Air Force HH-60G configuration; a major engineering, modification and integration effort.

SES is supporting the conversion of Army UH-60L helicopters to an Air Force HH-60G helicopter (L2G) through a program for the US Air Force Life Cycle Management Center, Warner Robins AFB. L2G entails an aggressively planned, high-value program, including direction and oversight of multiple subcontractors. This effort comprises an extremely complex conversion requiring the incorporation of 72 airframe and avionics modifications.

With the successful delivery of the first HH-60G aircraft, SES and its team of subcontractors have provided the Air Force a means to economically replace CSAR aircraft lost in combat that directly benefits our men and women serving in harm's way.

UH-60A FMS Modifications and C-17 Delivery

In support of Foreign Military Sales (FMS) and using aircraft selected from the BEST program, SES performed modifications for an FMS customer to include: aircraft receipt, storage, pre-inspections, purchasing, Phased Maintenance Inspections (PMI 1 and 2), Maintenance test flights (MTF), paint, acceptance support; three C-17 loadouts as well as OCONUS delivery support of multiple UH-60A helicopters.

In support of Foreign Military Sales (FMS) and using aircraft selected from the BEST program, SES performed modifications for an FMS customer to include: aircraft receipt, storage, pre-inspections, purchasing, Phased Maintenance Inspections (PMI 1 and 2), Maintenance test flights (MTF), paint, acceptance support; three C-17 loadouts as well as OCONUS delivery support of multiple UH-60A helicopters.

This is the third such program in which SES has delivered aircraft to a foreign customer using strategic lift with delivery support provided to the foreign customer.

Armed 407 Aircraft - Full Rate Production and STRATAIR Delivery

The Armed 407 program was a quick reaction Foreign Military Sales (FMS) effort to provide more than 20 armed Bell 407 reconnaissance helicopters to a foreign military partner in minimal time. The effort involved the installation of FAA-approved modifications as well as a militarized Mission Equipment Package (MEP) and numerous other modifications.

The Armed 407 program was a quick reaction Foreign Military Sales (FMS) effort to provide more than 20 armed Bell 407 reconnaissance helicopters to a foreign military partner in minimal time. The effort involved the installation of FAA-approved modifications as well as a militarized Mission Equipment Package (MEP) and numerous other modifications.

The complexity of this program resulted from transitioning a development program from a partner supplier, PIF/JVYS, and standing up a production facility capable of producing IA407 aircraft within cost, schedule and quality requirements.

As part of the effort, SES assembled approximately 100 kits per aircraft. The kits ranged in size from one part to approximately 100 parts per kit and contained a combination of GFE, purchased, and manufactured parts and materials.

This effort highlighted the complexity and maturity of SES’ aircraft modification facilities and personnel and the company’s ability to process a large number of aircraft. The figure below shows the fully loaded production line.

The Production/Fielding phase consisted of the IKPT for crew and maintainers, production, and delivery of aircraft in country. SES installed avionics, surveillance, survivability and communications upgrades on this effort. Additionally, SES developed all operator and maintainer publications for this variant. The Sustainment phase consists of Contract Logistical Support (CLS) and pilot/maintainer training after delivery of aircraft.

Block 1 AH-64D Apache Pre-Modification Offload Effort

For the past 6 years SES has conducted the Apache Pre-modification Offload Effort for Boeing. Work includes depopulation of the Block 1 AH-64D airframe, inspection and repair of assemblies and details to a serviceable condition in accordance with the Input Control Document (ICD) and additional written instructions as applicable. Since 2010, SES has maintained a production schedule that supports the AH-64E Production Line at Boeing (Mesa). We have inspected and repaired components per the IETM/DMWRs/Boeing Disposition which allows significant cost savings to the USG. In the past 4 years alone, SES has completed the depopulation of components from AH-64 airframes, repairing over 131 airframes, inspecting, repairing, and returning to service over 115,000 components, and kitted and shipped components per the customer’s instructions.

For the past 6 years SES has conducted the Apache Pre-modification Offload Effort for Boeing. Work includes depopulation of the Block 1 AH-64D airframe, inspection and repair of assemblies and details to a serviceable condition in accordance with the Input Control Document (ICD) and additional written instructions as applicable. Since 2010, SES has maintained a production schedule that supports the AH-64E Production Line at Boeing (Mesa). We have inspected and repaired components per the IETM/DMWRs/Boeing Disposition which allows significant cost savings to the USG. In the past 4 years alone, SES has completed the depopulation of components from AH-64 airframes, repairing over 131 airframes, inspecting, repairing, and returning to service over 115,000 components, and kitted and shipped components per the customer’s instructions.

Based on the success of this program, SES was selected as the Boeing Supplier of the Year for Aerospace Support in 2014 from among 13,000 Boeing suppliers in 47 countries.

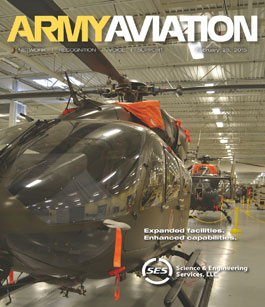

CH-47F Fielding Support Program

SES operates the CH-47F Maintenance Work Order Center (MWOC) in Huntsville Alabama at our newly remodeled South Hangar. At the new MWOC, SES has installed various modifications to include the Product Improvement Program I (PIP I), while simultaneously conducted scheduled / unscheduled maintenance as required. Additionally, SES is conducting ferry flights for over 169 aircraft from the CH-47F Production Facility (Ridley Park, PA) to gaining units and/or to New Equipment Training (NET) sites.

SES operates the CH-47F Maintenance Work Order Center (MWOC) in Huntsville Alabama at our newly remodeled South Hangar. At the new MWOC, SES has installed various modifications to include the Product Improvement Program I (PIP I), while simultaneously conducted scheduled / unscheduled maintenance as required. Additionally, SES is conducting ferry flights for over 169 aircraft from the CH-47F Production Facility (Ridley Park, PA) to gaining units and/or to New Equipment Training (NET) sites.

UH-72A Reconfiguration

- Built kits to mod additional aircraft

- Inspected aircraft for discrepancies that impact availability

- Modified standard components

- Installed required modifications

- Painted all aircraft at our on-site paint booth

- Placed the aircraft in flyable storage or conduced ferry flights to Ft. Rucker, AL

This modification effort has resulted in on-time delivery of the newest training aircraft for IERW in order to meet the Army’s training requirements.

Building Partner Capacity

In our continuing support to the US Navy and it’s Building Partner Capacity for the Royal Malaysian Air Force, and in partnership with Integrated Surveillance and Defense (ISD) and PT Dirgantara (PTDI), SES inducted the first Construcciones Aeronáuticas SA (CASA) aircraft CN-235 at PTDI’s facilities in Bandung Indonesia. The SES team will perform engineering for modifications associated with the unique RMAF aircraft configuration, manufacture, install, test, provide a Technical Data Package (TDP) to facilitate flight clearance approval from the Malaysia Director General Technical Airworthiness (DGTA), provide the sustainment recommendation, and provide a training package (Pilot, Operator and Mission System maintenance) for the RMAF ISR Aircraft System onboard three (3) Customer Furnished Equipment (CFE) CN-235 aircraft.Unmanned Systems